|

(c) 2012 - 2017 * updated MAR 2020 |

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

||||||||||||||||||||||||

|

|

|

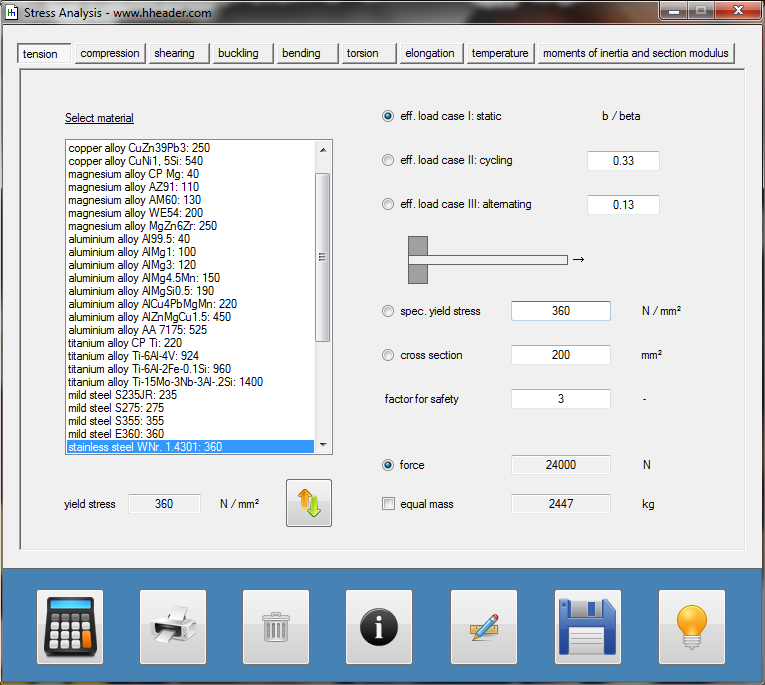

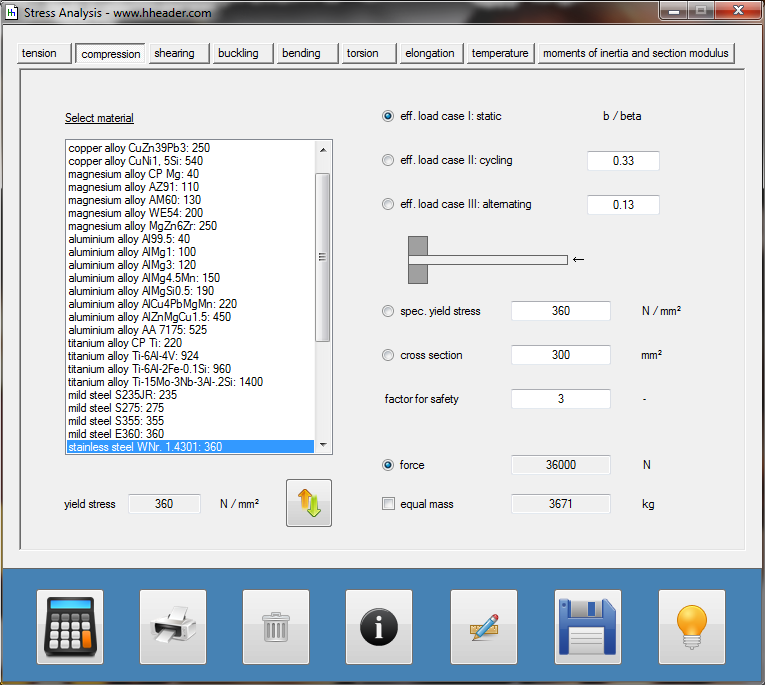

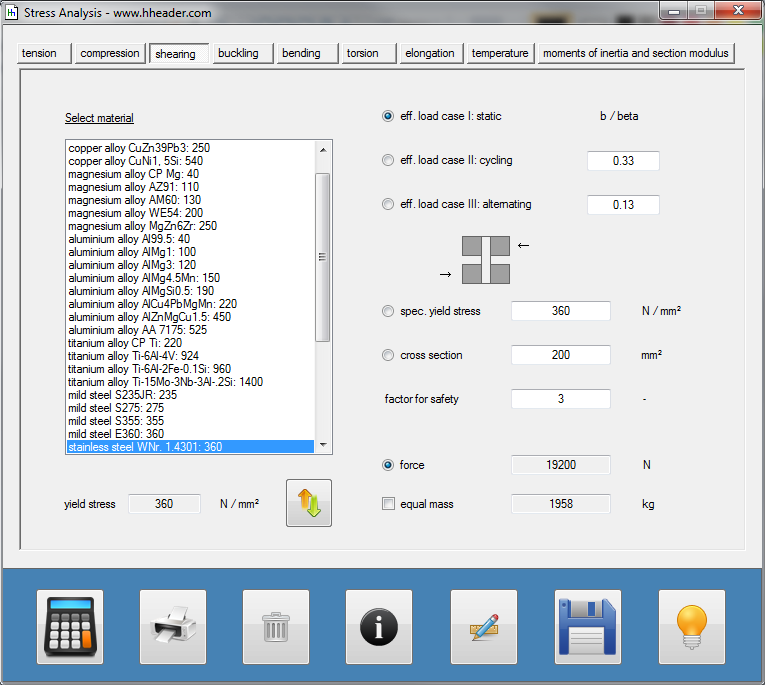

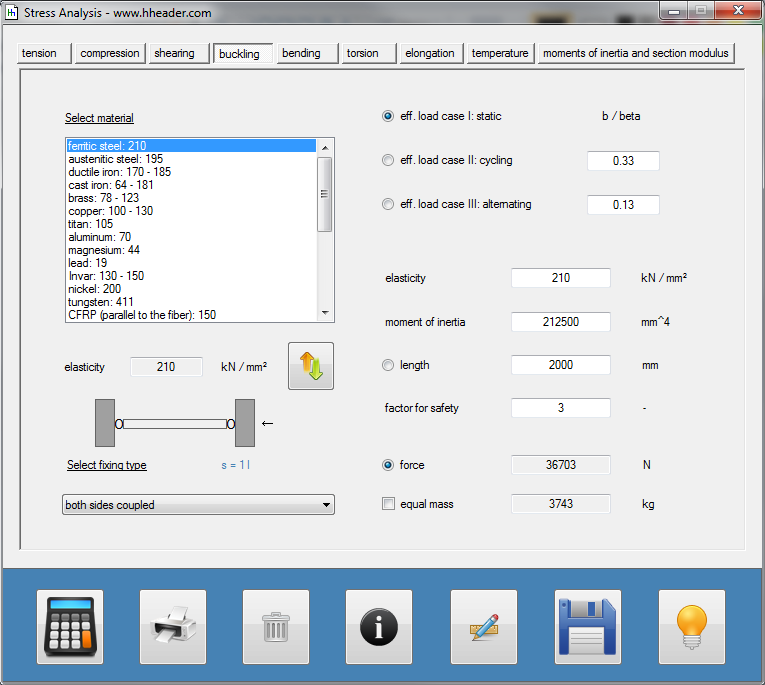

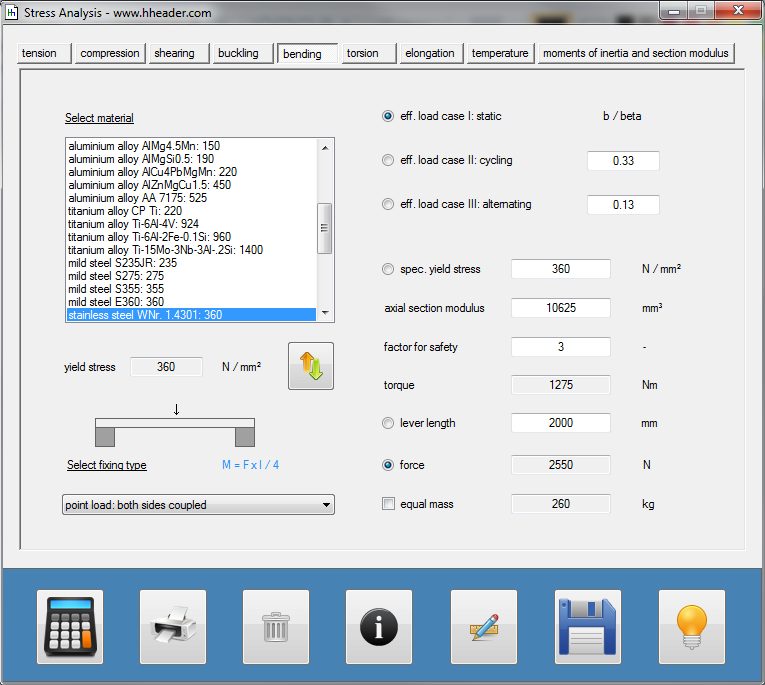

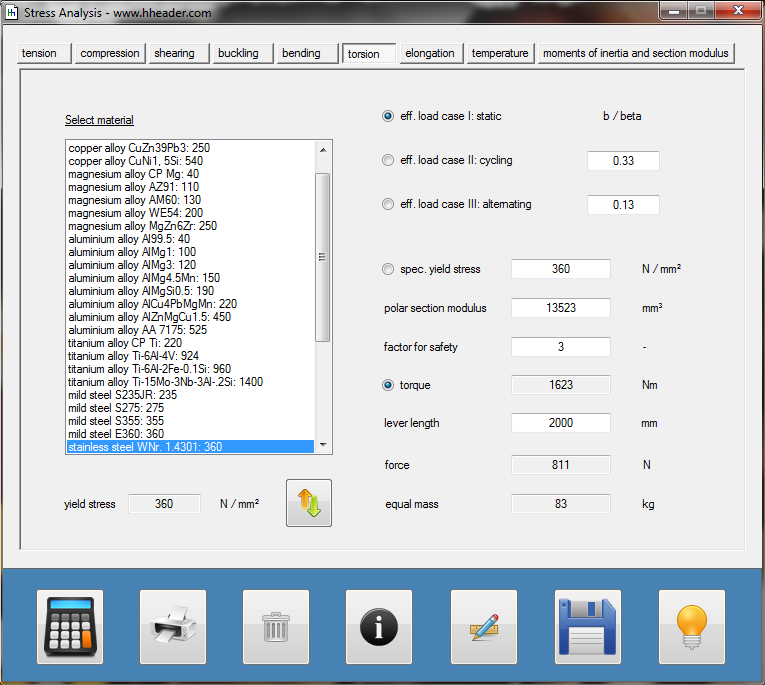

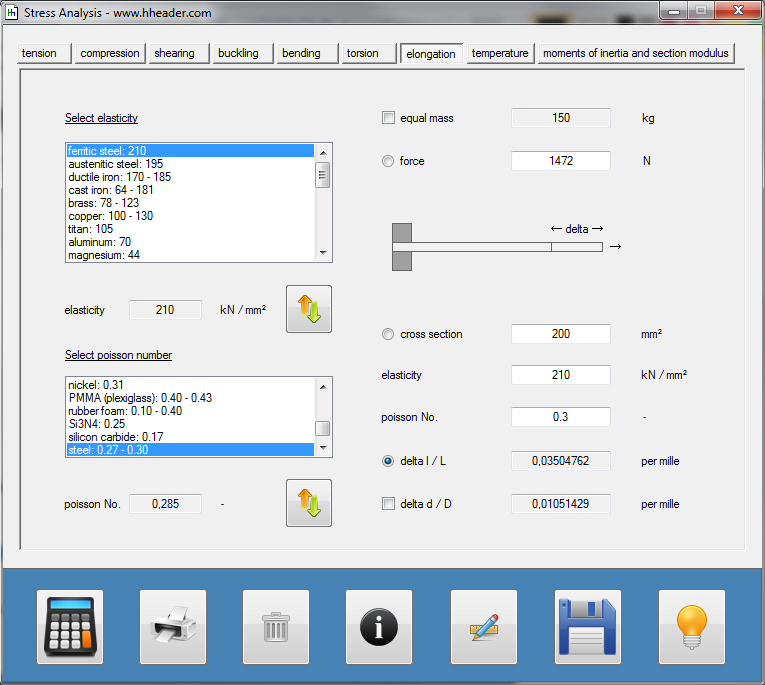

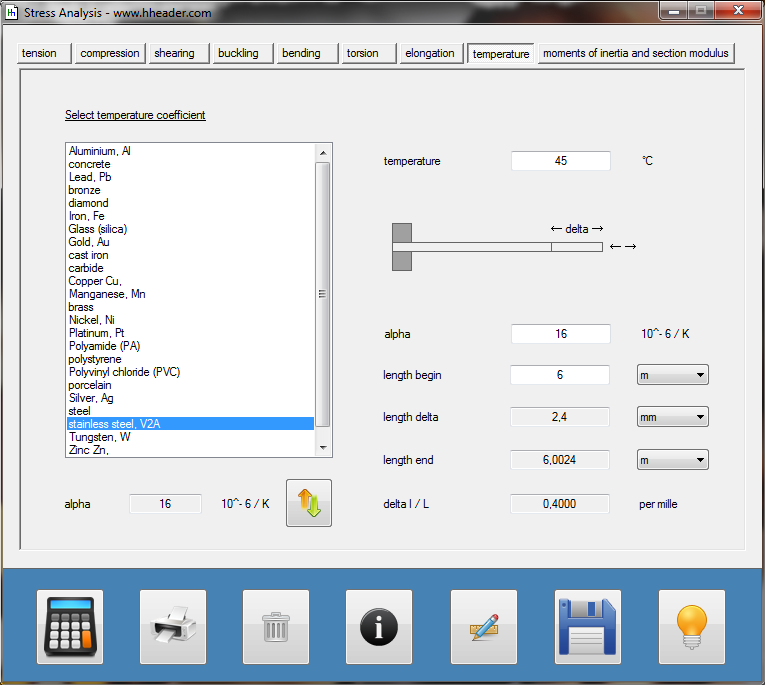

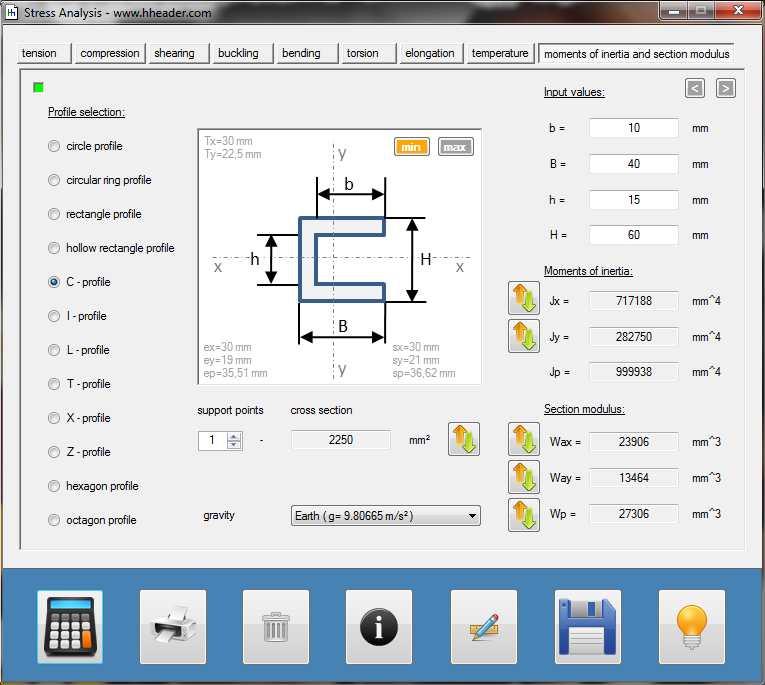

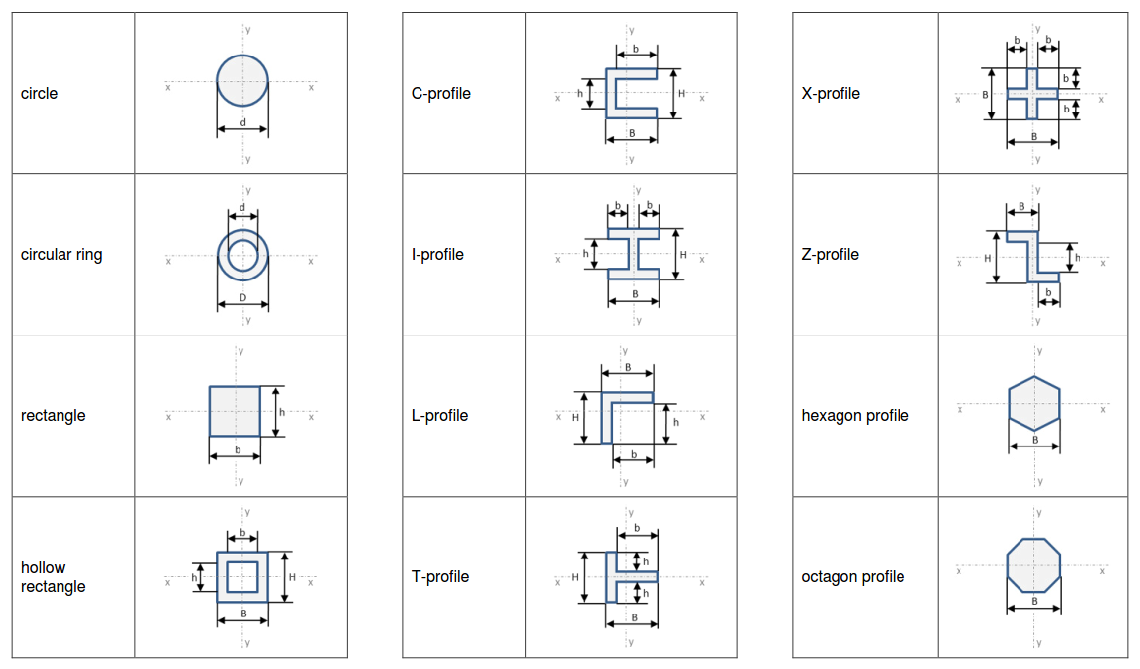

Category 6 - Mechanical: Stress AnalysisSupports, beams, clamps or any other imaginable construction or mounting is exposed to different kinds of mechanical stressing. It can be expected that in practice very rarely or even never only one of these kinds occurs. The question is which kinds are significant and which are insignificant. In case if more than one kind of stressing is significant, they have to be brought into focus one by one. The typical kinds of mechanical stressing are: tension, compression, shearing, buckling, bending, torsion. For these calculations a safety factor and the effective load case can be considered. The required moments of inertia and the required moduli can be determined as well. Calculations for the elongation by force and temperature are also provided. |

||||||||||||||||

|

|

||||||||||||||||

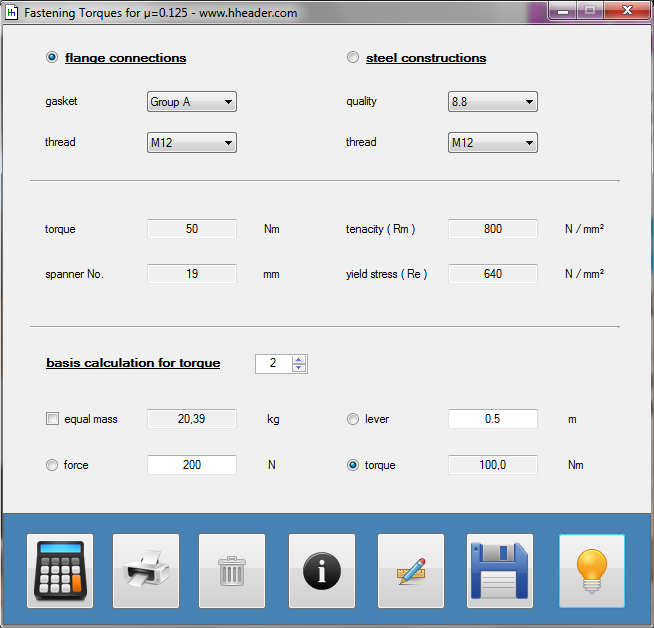

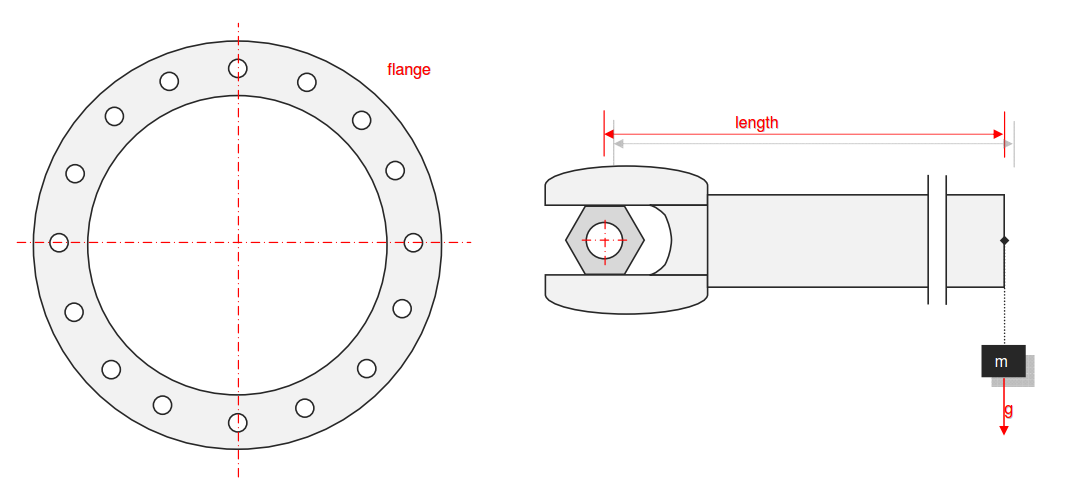

Category 6 - Mechanics: Fastening TorquesOf course screws and bolts should be tightened with the prescribed fastening torques. For the mounting works on site protocols for the proper fastening of the used screws and bolts are often demanded. If not otherwise stated or specified the fastening torques which are valid in general can be determined by this program. Regarding the basis for the determination the fastening torques are divided into two different types. Type One: fastening torques for the mounting of steel constructions, supports and consoles (based on the quality and the thread diameter). Type Two: fastening torques for the connection of flange joints (based on the gasket type and the thread diameter). |

||||||||||||||||

|

|

||||||||||||||||

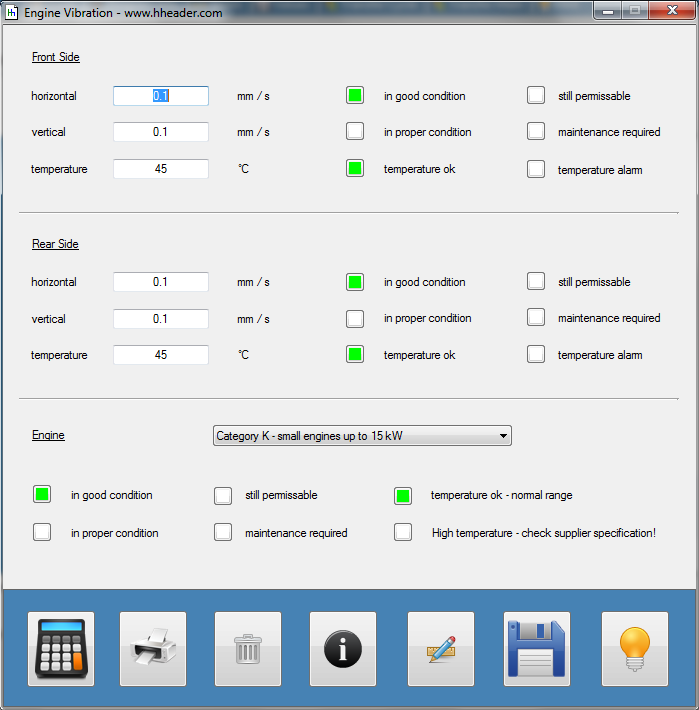

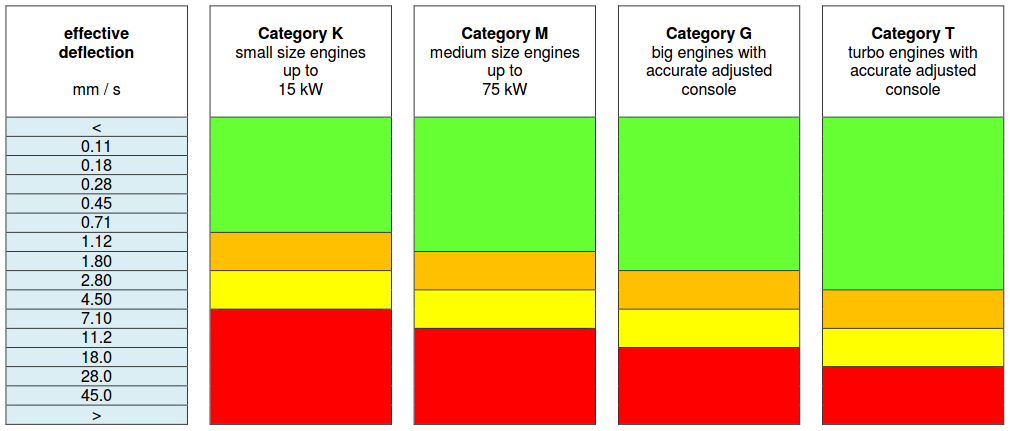

Category 6 - Mechanics: Engine VibrationsDifferent rules (e.g. the German Rule VDI 2056) define the permissible vibration rates for different aggregates on site. The vibration rates for operated aggregates have to be determined and evaluated regularly. Therefore special instruments are used that measure the deflection of the aggregate while it is in operation. The relevant unit is millimeter per second [mm / s]. Depending on the type, respectively the power rate of the aggregate, there are corresponding limit values defined for an accurate evaluation of the conditions regarding the vibration. |

||||||||||||||||

|

|

||||||||||||||||

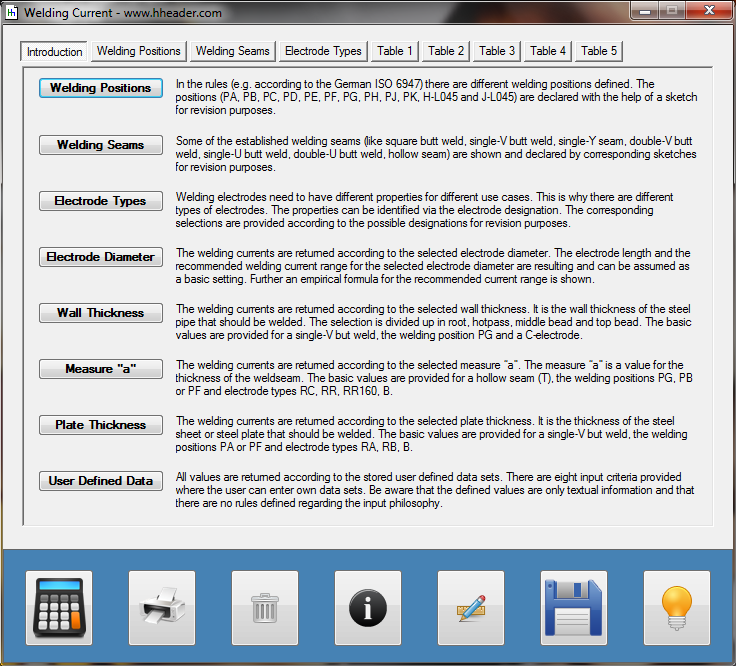

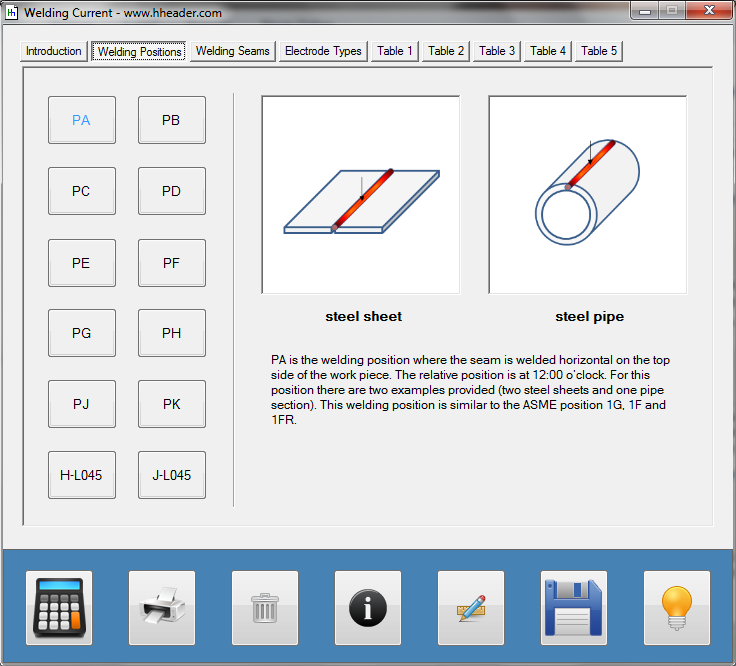

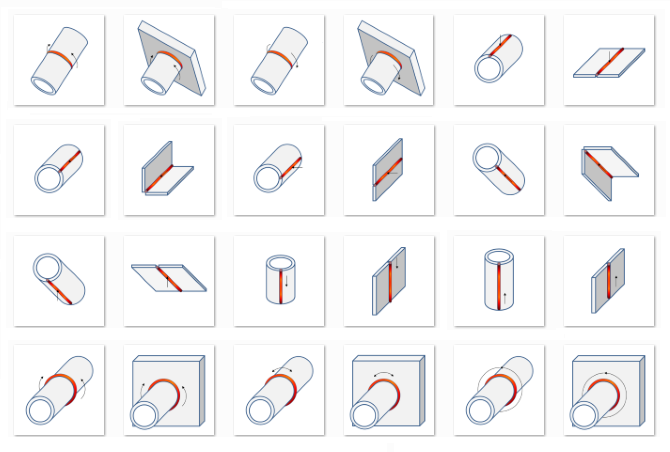

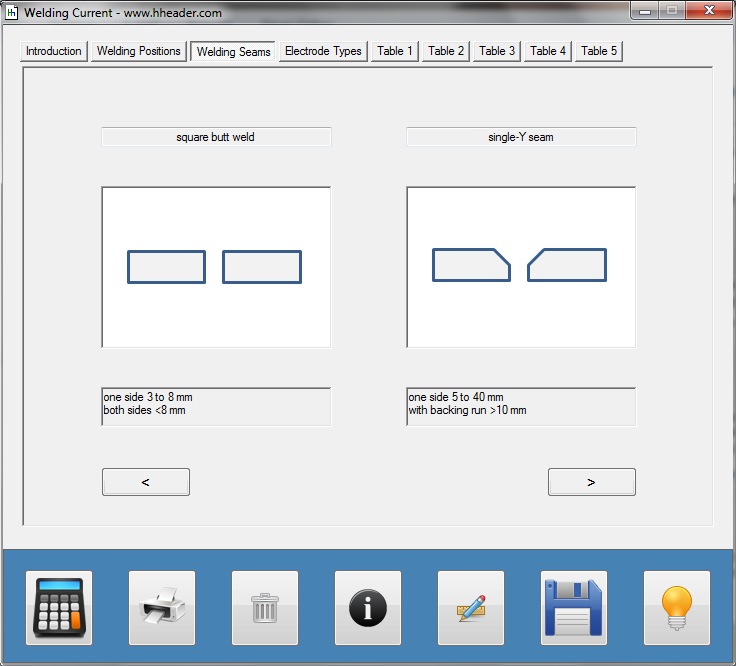

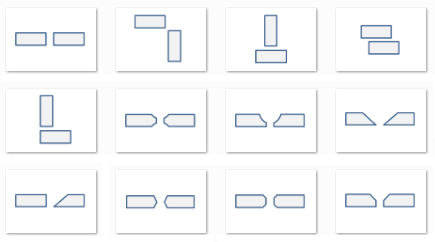

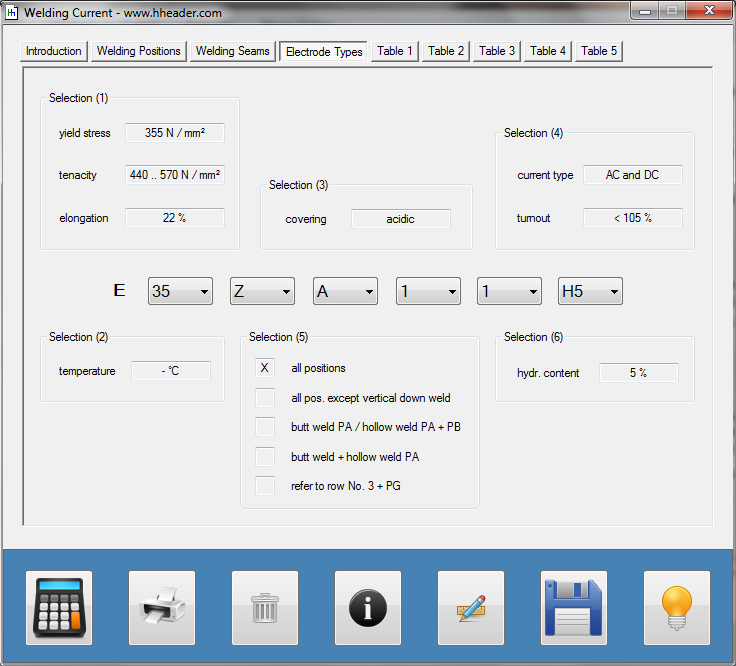

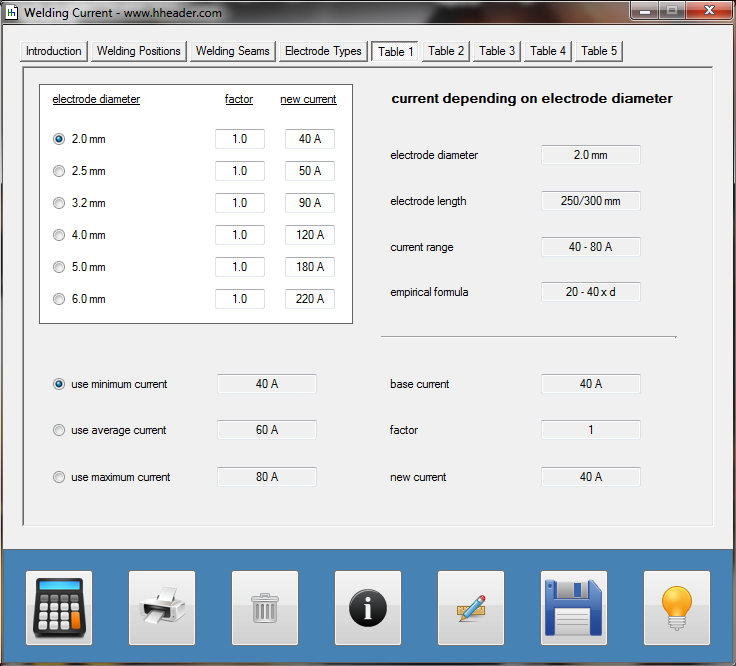

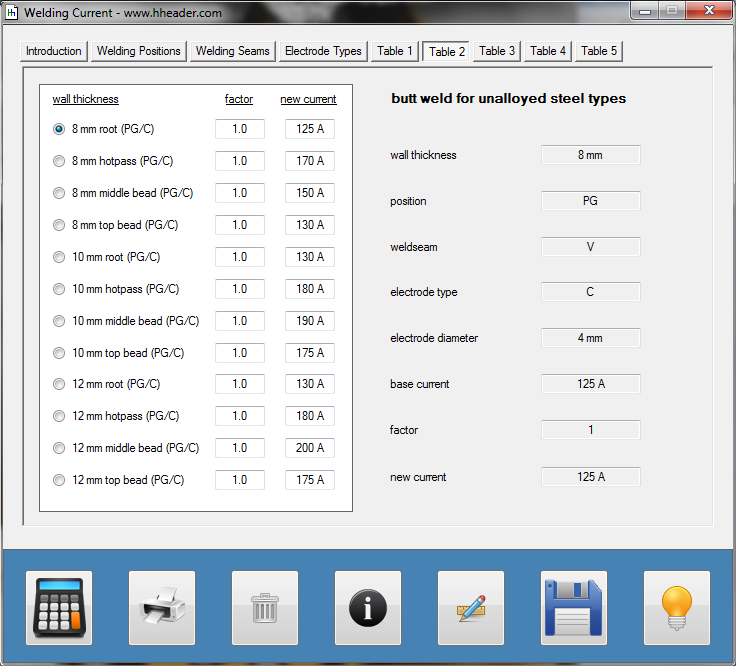

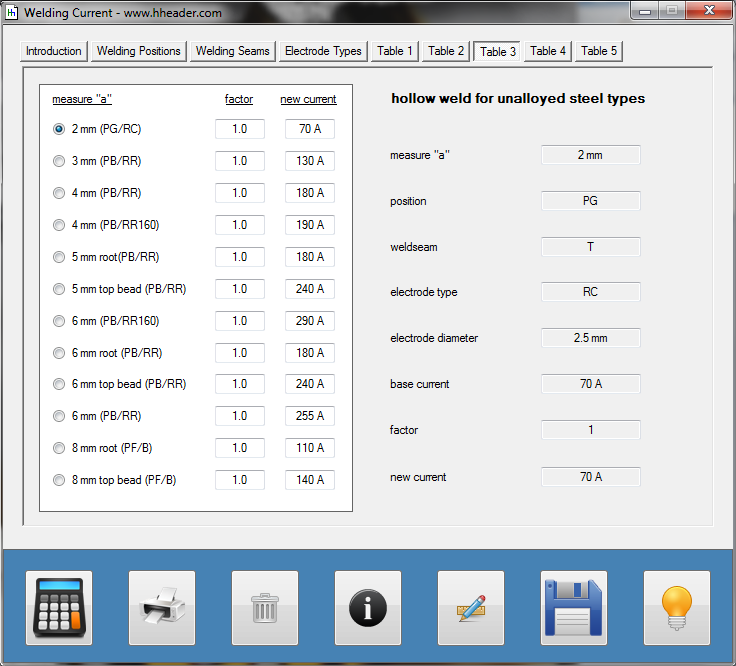

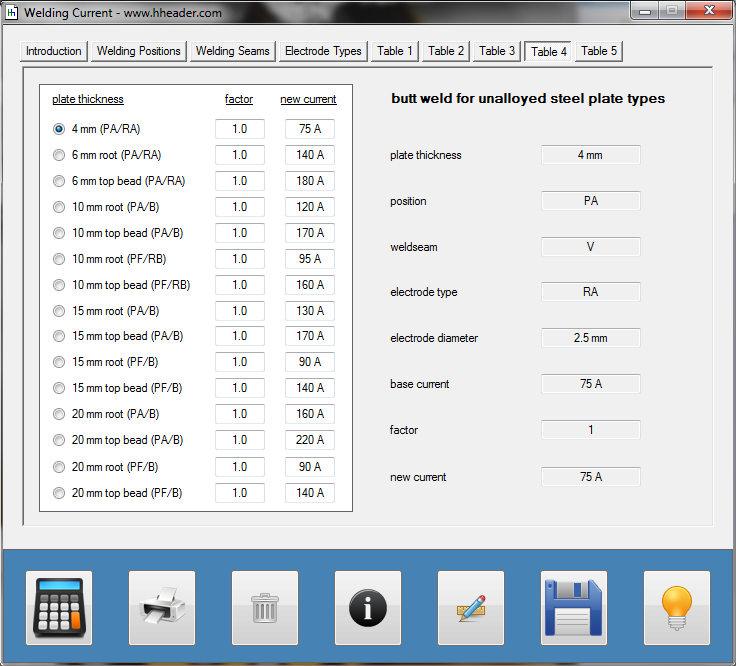

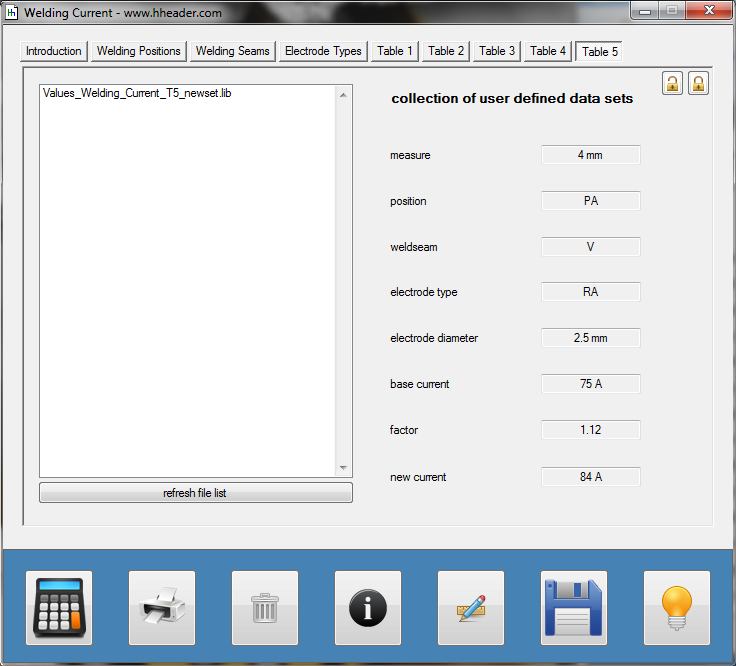

Category 6 - Mechanics: Welding CurrentThe program provides internal tables giving back the corresponding welding currents for arc welding with electrodes. The basis table values for the current are for unalloyed or low alloy steel types. For alloyed or high-alloy steel types the values have to be reduced because of the increased core rod resistance. The real proper current has to be adjusted in practice. For documentation purpose there are factors provided for each table. They can be set according to the in practice determined values. Afterwards the values can be stored in a data set. Thereby it is possible to create individual data sets for many different use cases. |

||||||||||||||||

|

|

||||||||||||||||

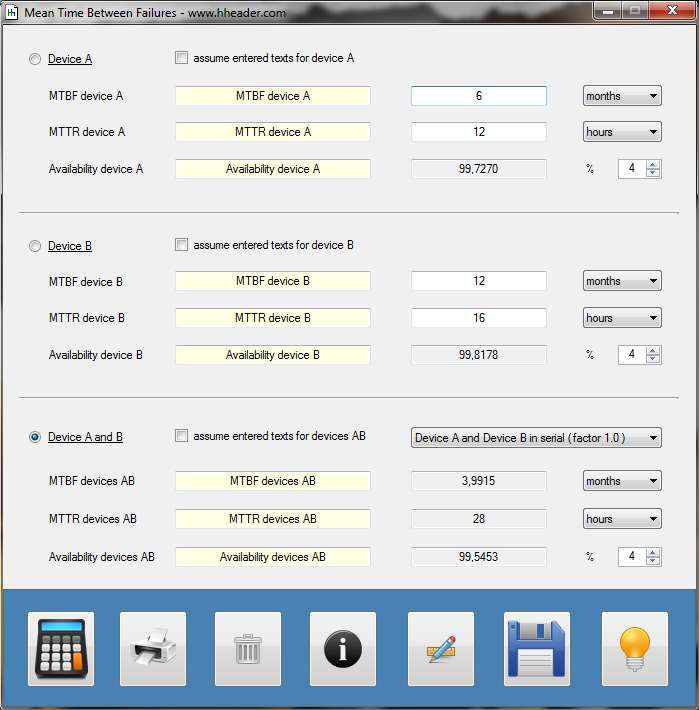

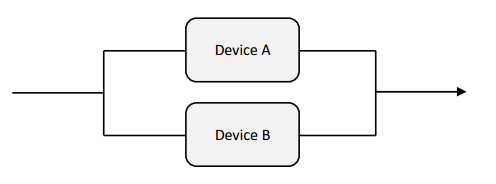

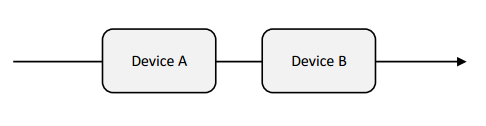

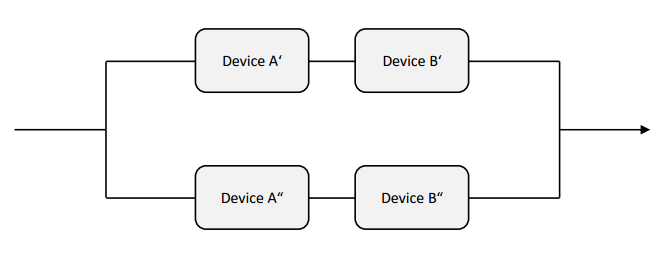

Category 6 - Mechanics: Mean Time Between FailuresThe “Mean Time Between Failures” (MTBF) is the average time that elapses from one significant failure to the next significant failure of an operated system or device. It is obvious that the mentioned failures are predictable failures. A significant failure in this case means a fault or error effectuating the system or device massively, so that it cannot be fully operated with its designated functionality anymore. Especially for single engineered system the MTBF can be an interesting value. It is also not too rare that the customer or contractor demands different calculations regarding the MTBF in order to get an overview about the availability of the installed system. |

||||||||||||||||

|

|

||||||||||||||||

|

||||||||||||||||

|